Industrial Laminators

WALCO® powered by NOVACEL offers the industry’s most extensive range of lamination machines for the application of temporary processing and protective films for industrial use, as well as permanent films for traffic sign applications. Built on 60 years of shared experience from engineers in the United States, Italy, and France, WALCO® designs laminators that are innovative, reliable, robust, and safe.

WALCO® roll laminators deliver market-leading performance on any surface, ensuring optimal protection and processing efficiency.

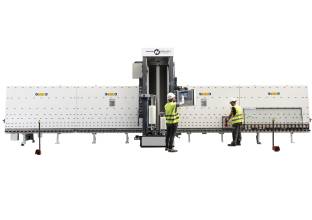

Horizontal laminators

Vertical laminators

Industrial Laminators

WALCO® industrial laminators are high-performance machines designed for fast, easy, and flawless lamination of protective and processing films - without wrinkles or bubbles - for industrial use, as well as permanent films for traffic sign applications, on flat surfaces of any size. Both in-line and off-line systems boost productivity, fully aligned with your production requirements.

WALCO® manual and automatic cutting laminators adapt to your budget and substrate volume:

- Manual laminators are ideal for low-volume applications, delivering perfect lamination on metals, plastics, wood, flat glass, and more.

- Automatic laminators are the most advanced, featuring WALCO®’s patented cutting system for precise edge-to-edge film application. The Precision Technology allows negative cuts (small margin free of film), positive cuts (film slightly beyond sheet edges), or exact edge-to-edge cuts, ensuring maximum flexibility.

WALCO® horizontal and vertical laminators integrate seamlessly into production lines, prioritizing safety and ease of use. Ergonomic features like intuitive control panels, foot controls, and user-friendly operation ensure high-quality output.

All WALCO® industrial laminators are custom-built to meet specific requirements, including automatic conveyors, electrostatic bars, safety systems, LED lights, cranes, stacking devices, and more. They provide reliable lamination for protective and processing films in industrial applications, as well as permanent films for traffic signs.

Reliable

WALCO® powered by Novacel film application machines for process films, temporary protective films, permanent films, or roll coatings stand out for their reliability and durability. Backed by several decades of experience in the design and global supply of laminators, WALCO® sets some of the highest performance standards in the industry, enabling customers to rely on their industrial laminators for over 15 years.

Innovation

WALCO® machines integrate advanced patented technologies to ensure optimal performance in the field of surface protection. Key innovations include:

- Automatic protective film cutting using a WALCO® patented rotating blade

- Electrostatic charge retention and positioning system

- Precise film application on panel edges

- Vertical film application with the vertical laminators range

This strategy of continuous innovation enables WALCO® to establish a strong and lasting presence in the market, offering solutions perfectly adapted to next-generation production lines. Thanks to these advancements, WALCO® 4.0 machines are fully compatible with automated industrial environments, ensuring precision, reliability, and productivity.

Safe

Safety is a core, daily priority at WALCO®, ensuring protection for both employees and industrial equipment. This commitment begins within WALCO® facilities, where all staff strictly follow protocols to maintain a secure working environment and guarantee the proper care, operation, and longevity of all machines.

All WALCO® industrial laminators, are engineered and manufactured in compliance with European safety regulations, including the Machinery Directive 2006/42/CE, as well as American safety standards such as OSHA and UL. This ensures reliable, compliant, and safe operation in industrial production environments worldwide.

Beyond machine design, WALCO® extends its safety culture to every customer through comprehensive operator training, guaranteeing safe use, proper handling, and long-term performance of all laminating systems.

Ergonomic

All WALCO® laminators are designed to provide optimal ergonomic solutions for operators at every stage of applying protective films, permanent films, or coatings from film setup to its final application on the customer’s substrate.

Environmental Friendly

Environmental responsibility is a key priority for future generations. In the manufacturing of its laminating equipment, WALCO® uses more than 90% environmentally friendly materials, such as aluminum and stainless steel, for laminator frames. In addition, key components like shaft roll holders and application rolls can be revamped by WALCO® rather than replaced, reducing both waste and costs.